System Components

Welcome to

Cimat Global

CEO Message

"At Cimat Global, we pride ourselves on the immense experience of our staff and the state-of-the-art production facility. We work closely with our customers as their consultants to redefine their needs and execute with the best cost-effective solutions that suit perfectly their requirements."

Our Products

For more information, see Sandwich Panels, Pre-Painted Aluminum, Rolled Form Profile Sheets, C-Channels, Z Purlins, Curved Eaves, Trims, and Flashings.

01.

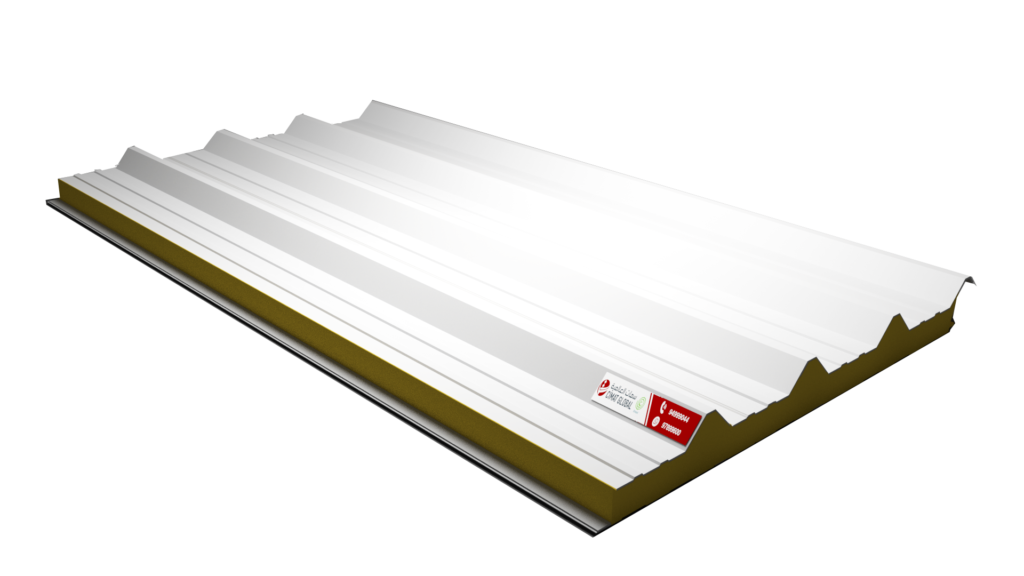

SANDWICH PANELS

A low-density core (PUF), a thin skin layer bonded on both sides, and an insulating layer between them are used.

02.

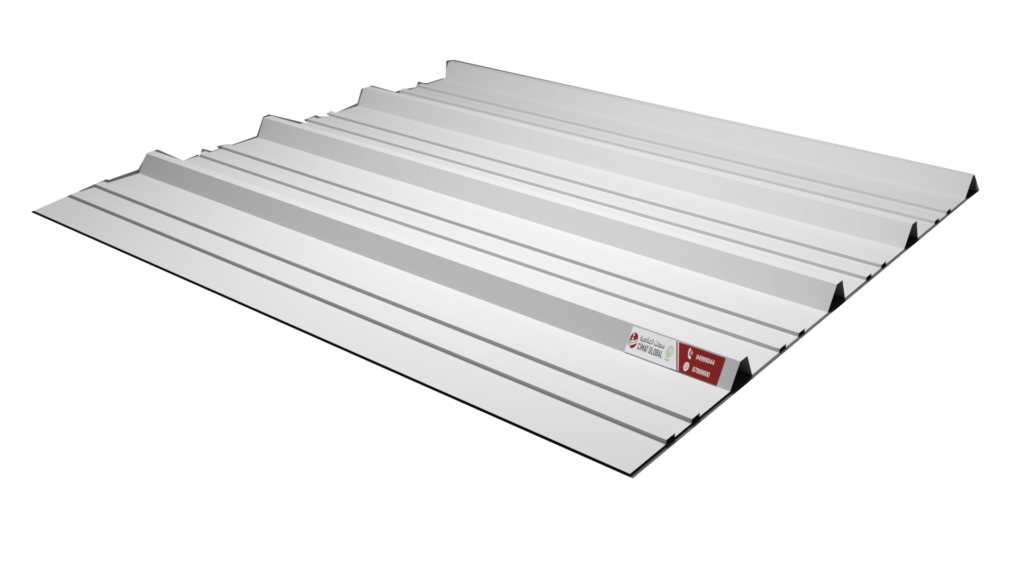

PROFILE SHEETS

Mainly used for roofing and cladding jobs in which thermal insulation is not a primary concern. Cimat Global creates its profile sheets from pre-painted galvanized (PPGI) metal sheet.

03.

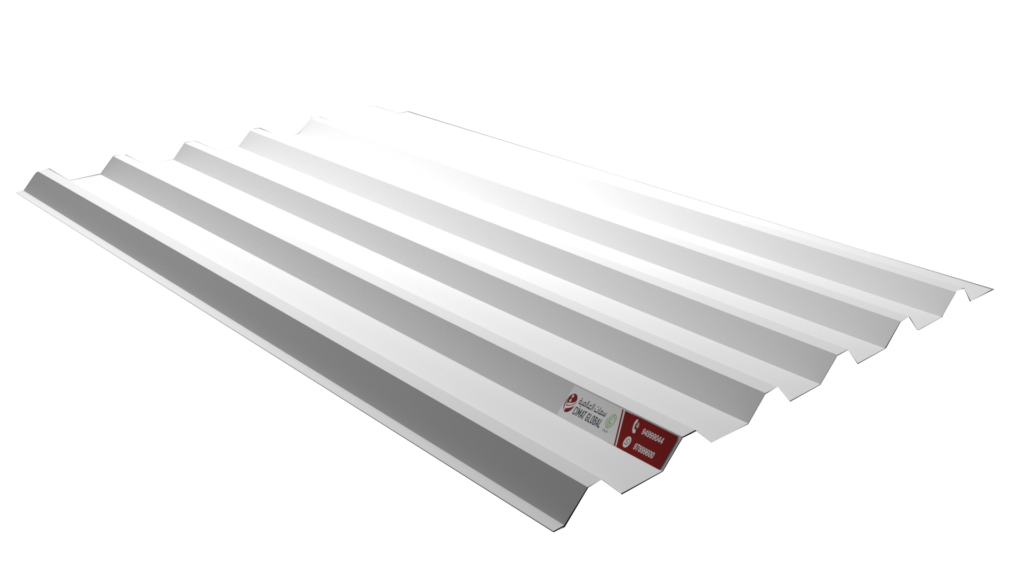

DECKING SHEETS

The metal deck is a structural panel element that acts as the the surface of a floor or roof.

01.

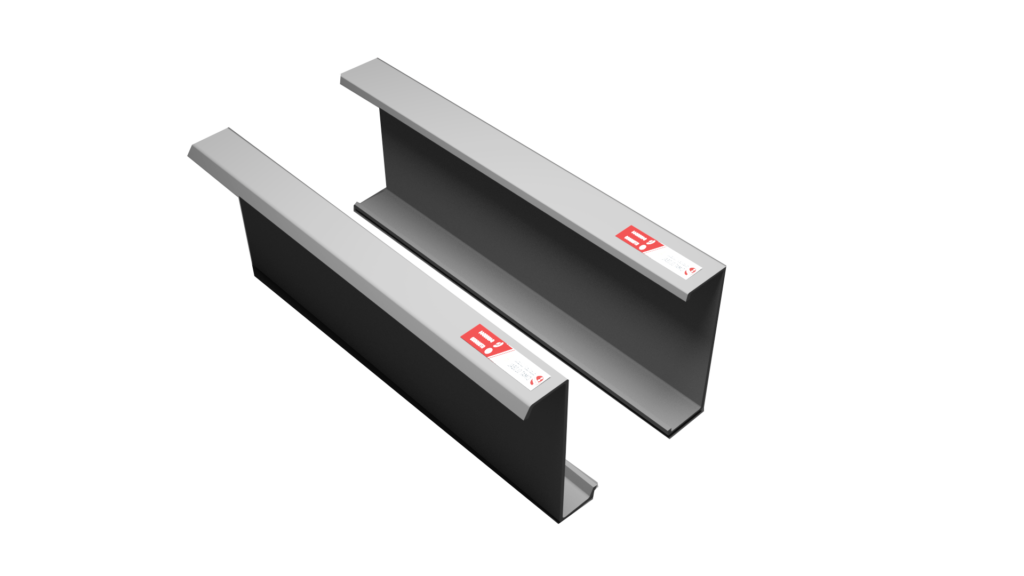

C & Z PURLINS

We offer Plain and punched GI purlins manufactured from high tensile steel having higher strength, long life and minimum weight.

02.

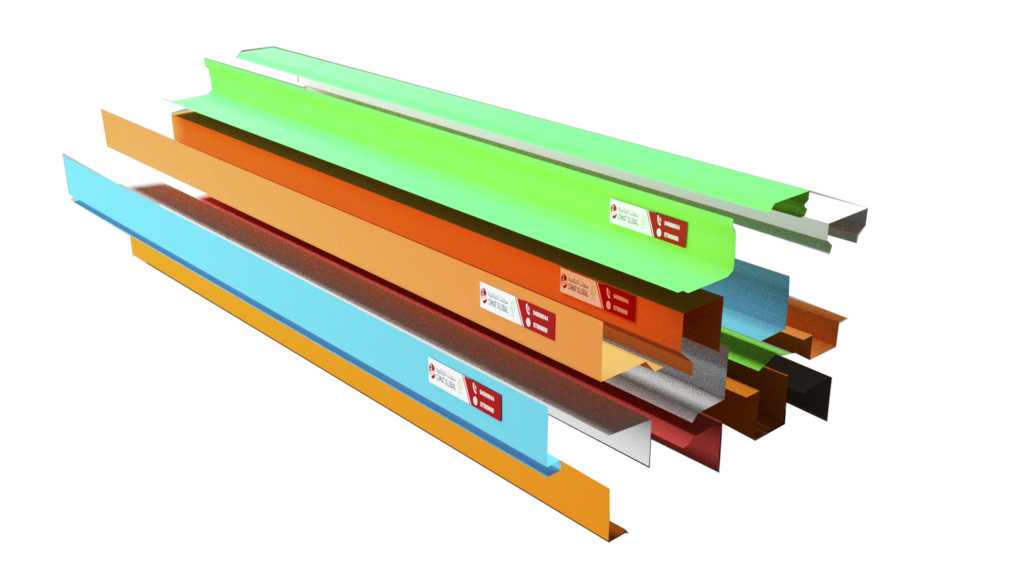

FLASHINGS & TRIMS

CIMAT offers a wide range of standard and customized flashings (GI, PPGI, and PPAL), Curved Eaves, Ridges, and Gutters as per the requirement.

03.

ACCESSORIES

Accessories include butyl tapes, filler blocks, Rockwool, roof ventilators, silicon sealants, PVC screw caps, purlin tapes, blind rivets, self-drilling screws, aluminum foil paper, polycarbonate skylight sheet, and Rockwool slabs.

Our working Process

- Consultation Understand the client's need and consult the best option.

- Proposal Preparing a proposal about all the details of the client's request.

- Manufacturing Manufacturing the product for the client's with precision and perfection.

- Delivery Preparing the product for delivery to the client's after manufacturing completion.